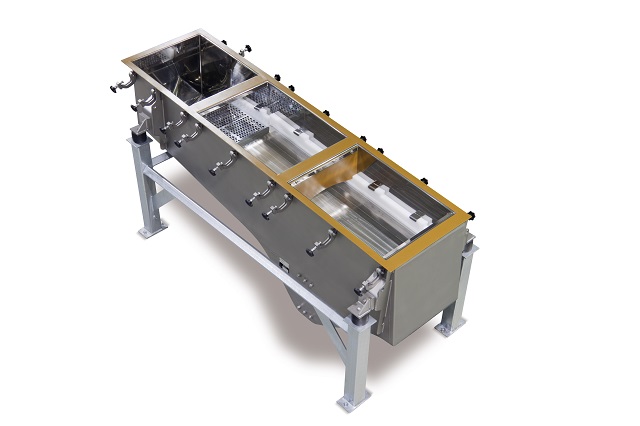

Benefits of control screening machines & protective screening machines

Pure products with the aid of protective screening

Without reliable protective screening, it is unfortunately possible for foreign bodies contained in the bulk material, such as screws, production residues or similar, to significantly disrupt downstream machines or systems. This also significantly reduces and jeopardizes the quality of the end product. To ensure consistently high quality, the control sieve shaker can be used at different points in the production process. The aim is to remove foreign bodies from the desired pure product. Smooth production processes are more important today than ever before. Complaints due to quality deviations or contaminated material are not only an economic problem, but also damage your company’s image. To raise the quality to a consistently high level, our control and protection sieve helps you, which is individually adapted to your requirements.