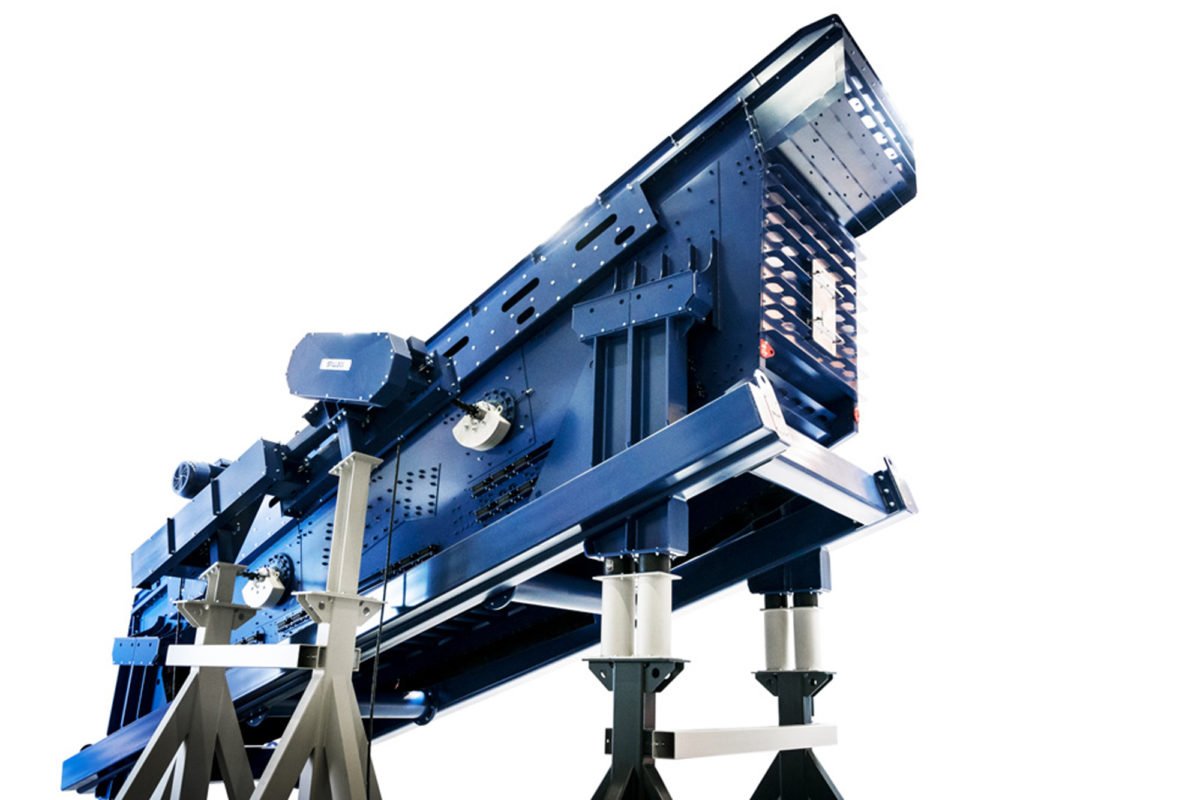

Use case

Classification of difficult-to-screen, sticky and moist materials

Materials for separating cuts from approx. 0.2 to 50 mm.

Screening machines must be reliable and powerful. Optimize the processing of your screening material with our flip-flow screens. The machine output guarantees a strong performance of your recycling system.

SPALECK flip-flow screens set the standard worldwide in terms of economy, reliability and efficiency.

If optimum screening performance, quality and the screening result are what count for you, then SPALECK expansion shaft technology is just right for you.

If you are interested, we will be happy to organize a tour of leading reconditioners who count on SPALECK. Just get in touch with us.

Contact usClassification of difficult-to-screen, sticky and moist materials

Materials for separating cuts from approx. 0.2 to 50 mm.

Moist, wet and dry material from inhomogeneous products such as recycling materials, building raw materials, compost, fertilizers, granulates, waste wood, …

Test your materialThe excitation of the base frame is achieved by unbalance by means of

Shaft and unbalance motor drive. This is attached to the

dynamic framework.

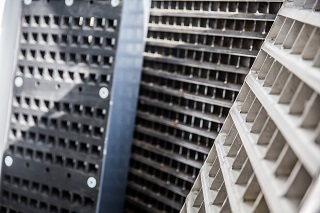

Two moving relative to each other at the same frequency

Frame systems compress or tension between the frames fixed

Screen mats.

The modular and compact design of the SPALECK flip-flow screening machine

enables individual adaptation to customer-specific tasks.

The ease of installation of the screen mats, the extension to a

Multi-deck design and the dynamic swing range adjustment are

Further equipment features.

The swinging cover can be opened without the need for tools and secures a

quick access to the screen mats.

The relative movement of the two frames to each other causes a so-called

“Trampoline effect” in the sieve mats. This effect leads to the following advantages:

– High acceleration of up to 50 g in the sieve mats

– Loosening up the product

Don’t buy your new screening machine off the shelf, but opt for the best solution for your screening task.

We build every single one of our screening machines 100% tailored to your application. This guarantees you the latest screening technology and optimum recycling and reprocessing.

Reference projects

With our screening technology, you are one thing above all: flexible & economical.

Uncompromisingly designed for the best sieving results AND user benefits, you can use your SPALECK sieve as you need it.

With the patented SPALECK expansion shaft cassette, you can convert your recyclable material screen into an expansion shaft in no time at all.

MoreWe build our SPALECK flip-flow screens in such a way that you can reprocess and recycle them in the best possible way.

This means that you minimize your maintenance and cleaning costs with flip-flow screens from SPALECK. At the same time, your employees can easily adjust the screening machine optimally to the respective screening material.

Our expansion shaft technology also offers you unique screening quality and performance in mobile processing.

More

Are your screenings particularly sticky and sticky? Fine! With our patented, easily retrofittable expansion shaft cassette, your screen linings will still stay clean!

SPALECK offers you many smart solutions for screening. Like our patented MultiZONE deck, for example. This provides you with several screening areas on one screening deck. This allows you to easily control the screen quality and flexibly adapt your screen to a wide variety of material flows.

Your screen material may change.

That’s why we have hundreds of different customized screen surfaces available for you and your applications.

Your employees can change the screen linings quickly and easily.