SPALECK Connect

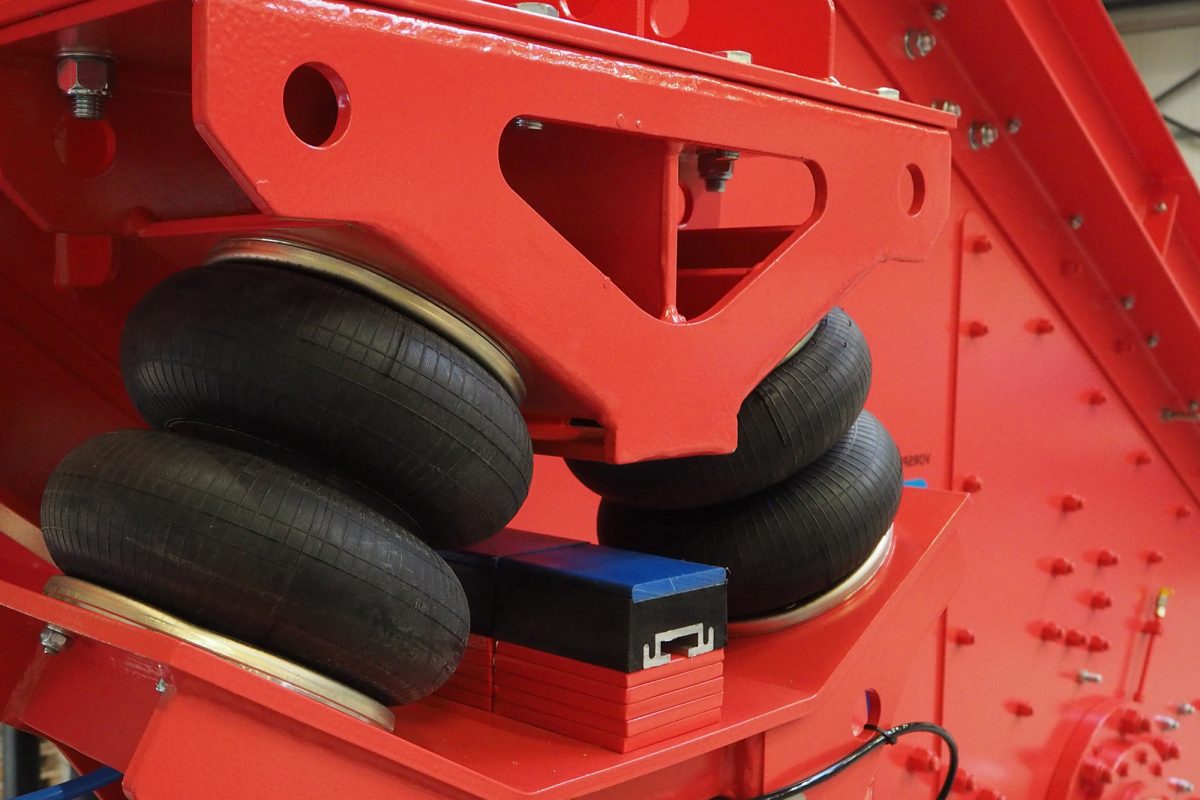

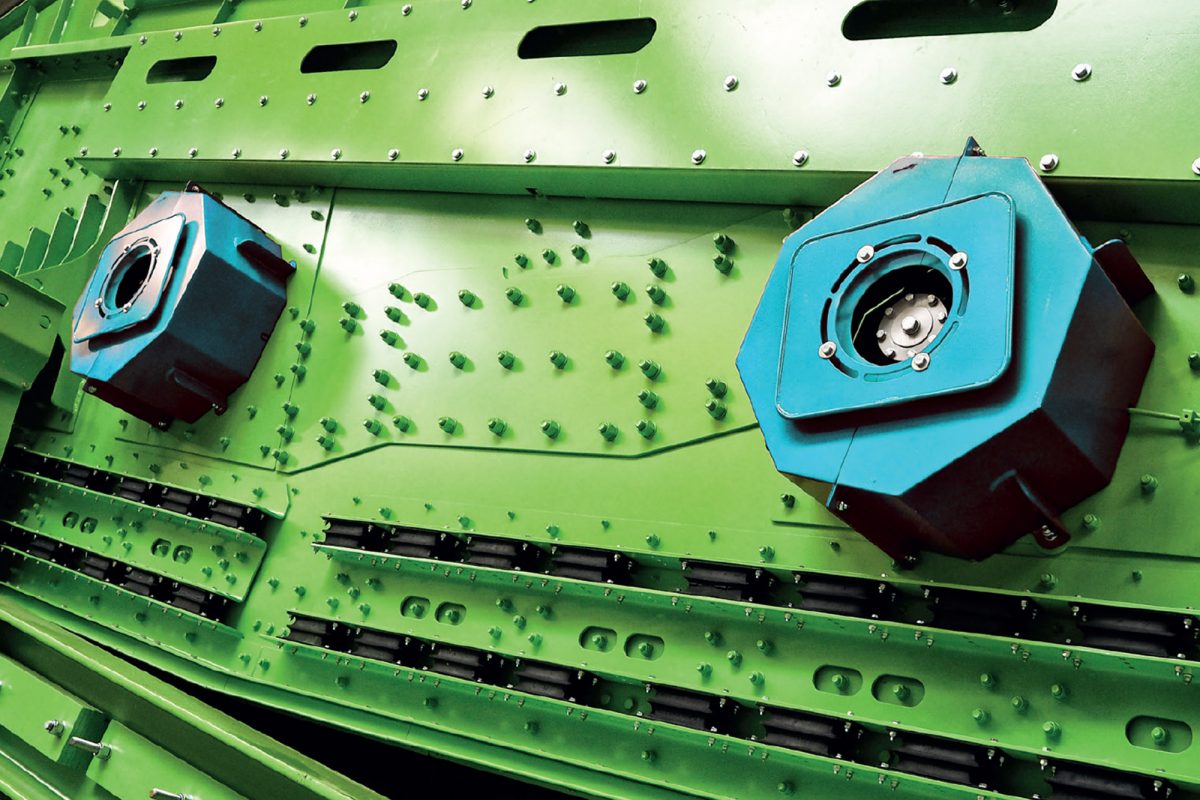

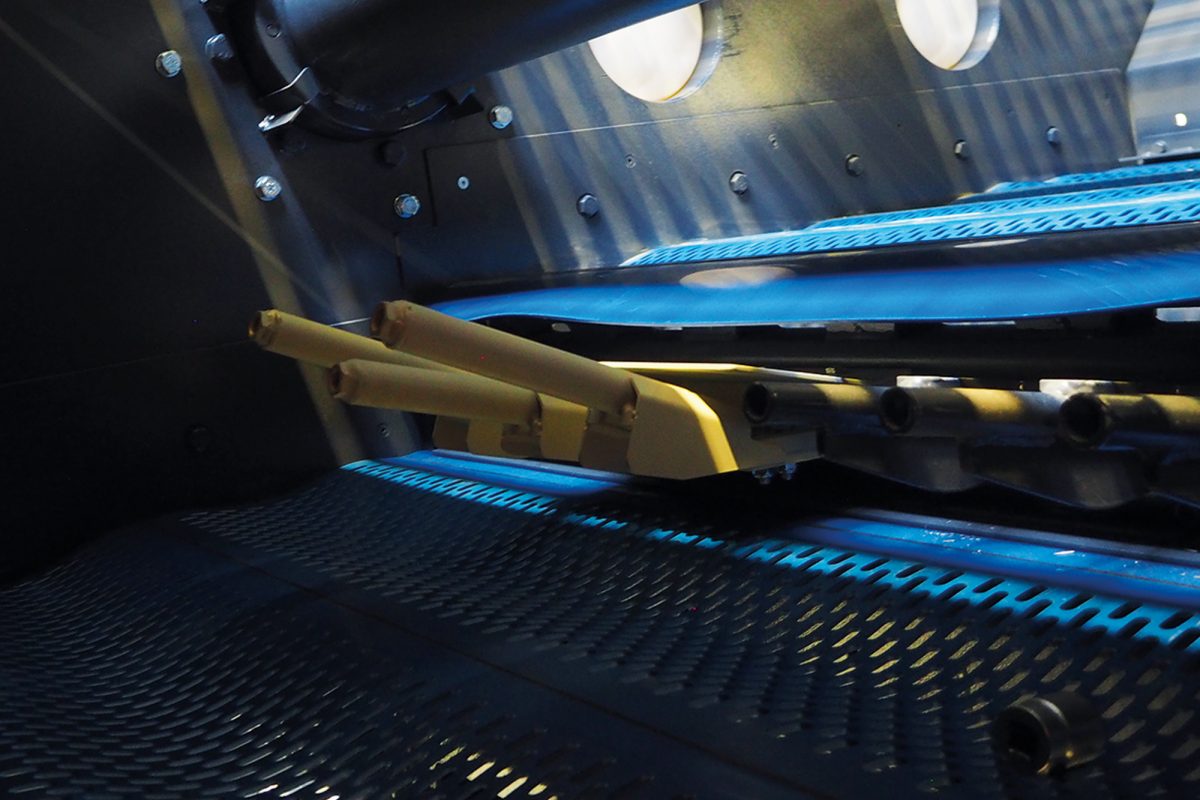

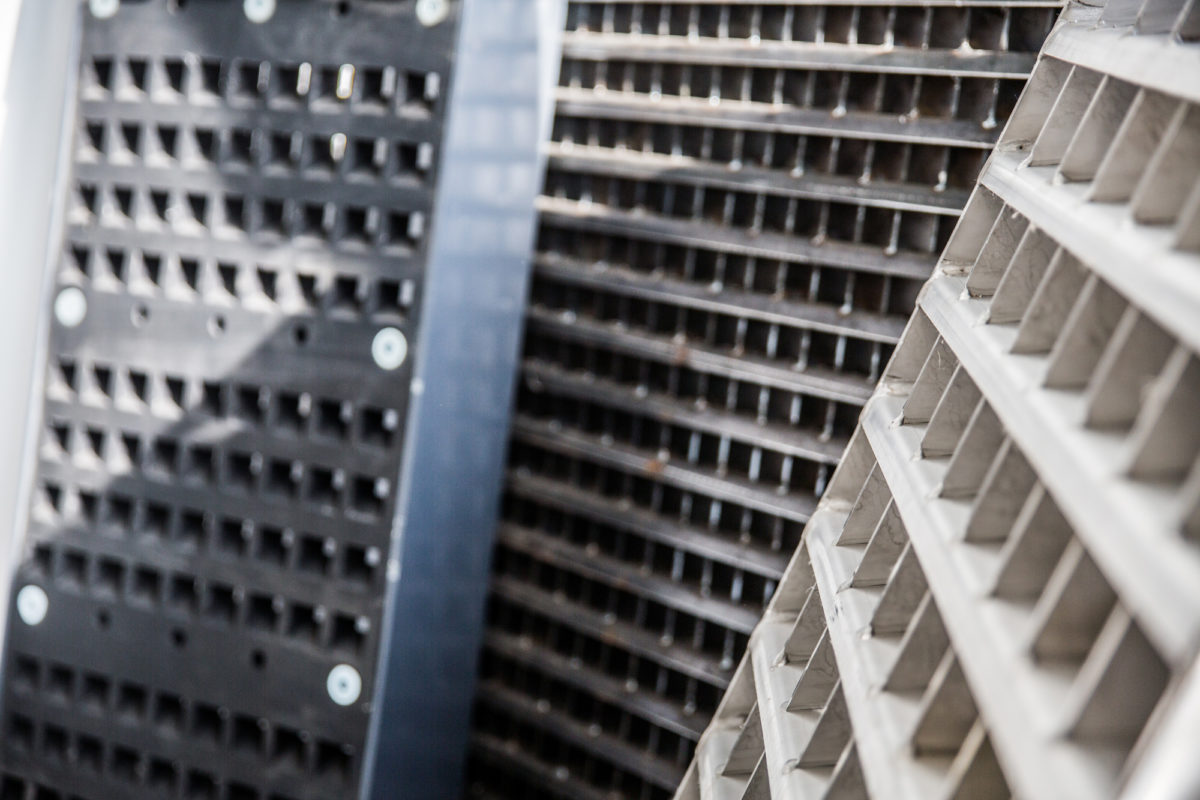

Vibration machine monitoring 4.0

Now also as an APP

With SPALECK Connect technology, you always have the performance details of your oscillating machine in view. In real time and on your smartphone if you wish. This ensures optimum performance and protects against machine breakdowns.

Inform now

USA

USA