What are overlength separators used for?

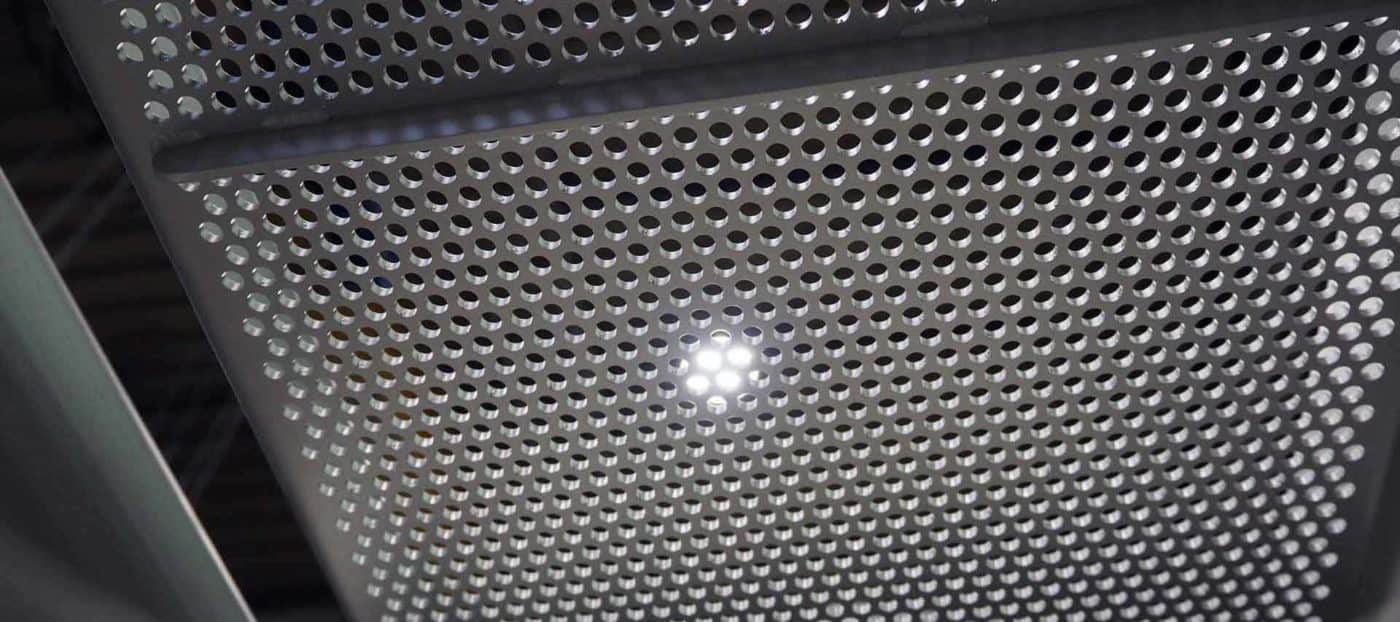

During the production of plastic pellets, excess lengths (“longs”) occur in the production process during start-up and shut-down, which interfere with the further processing of the pellets. The overlength separator is part of our range of screening machines for the chemical, pharmaceutical and food industries and helps you to screen these overlengths from the desired pellet size. In the jargon of processing technology, this involves separating the bad granulate from the good granulate. The overlength separator is a special form of control and protective screening for the separation of overlong material parts. If further screening of the granulate is required in addition to pure overlength screening, the use of a granulate screening machine is recommended.